Smart Tips About What Is VFD Disadvantage

Understanding the Flip Side

1. Initial Costs and Complexity

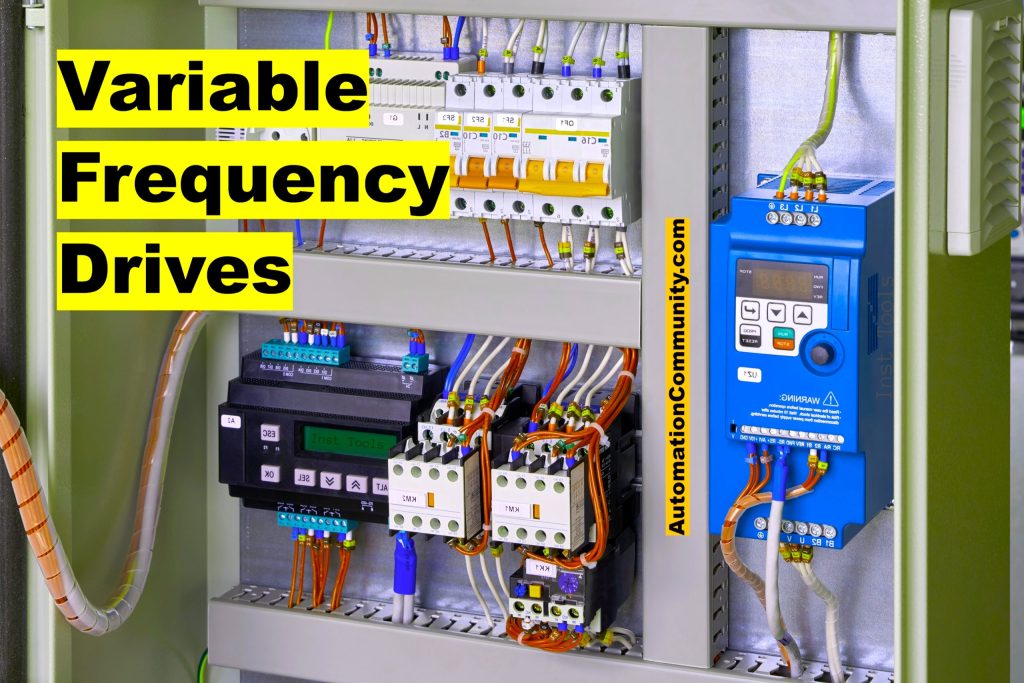

So, you're thinking about Variable Frequency Drives (VFDs), huh? Smart move! They're fantastic for controlling motor speed and saving energy. But let's not pretend they're perfect. Like that super-efficient car that costs a fortune to repair, VFDs have their downsides. One of the biggest? The upfront cost. These things aren't cheap. You're looking at a significant investment, especially if you're outfitting a whole factory.

Then there's the complexity factor. A VFD isn't just a plug-and-play device. They have parameters to configure, settings to tweak, and a whole language of their own. Imagine trying to assemble IKEA furniture without the instructions — frustrating, right? Well, setting up a VFD can sometimes feel like that if you're not familiar with the technology. You may need to hire a qualified technician or invest in training, adding even more to the initial expenses. Think of it as learning a new dance, some people get it quickly but some need more time.

And it's not just the initial setup. Ongoing maintenance can also be a bit more involved than with traditional motor starters. They have sensitive electronic components that can be affected by heat, dust, and humidity. Like a delicate flower, VFDs need a carefully controlled environment to thrive. Ignoring these needs can lead to unexpected downtime and expensive repairs. So, you need to factor in the cost of regular inspections, cleaning, and potential component replacements.

Ultimately, while VFDs save you money in the long run through energy efficiency, don't overlook the initial hit to your wallet. Budget wisely, understand the installation complexity, and remember those maintenance costs. It's all about weighing the pros and cons before diving in. You wouldn't buy a puppy without considering vet bills, would you? Treat your VFD the same way!

Harmonics and Electrical Noise

2. The Not-So-Silent Partner

Alright, let's talk about the elephant in the electrical room: harmonics. VFDs, while being energy-saving wizards, can also introduce harmonic distortion into your power system. Think of it like adding a bunch of off-key notes to a beautiful symphony — it can mess things up. These harmonics are basically unwanted frequencies that can cause problems for other equipment connected to the same electrical grid. It's kind of like having a noisy neighbor; their racket affects everyone around them.

These harmonic currents can overload transformers, cause overheating in conductors, and interfere with sensitive electronic equipment. Imagine your office computer suddenly acting up because the VFD in the HVAC system is throwing a harmonic tantrum. Not fun, right? You might even need to install harmonic filters to mitigate these effects, adding more costs and complexity to the project. It's like needing noise-canceling headphones just to get some peace and quiet.

And it's not just harmonics. VFDs can also generate electrical noise that can disrupt communication signals and cause malfunctions in other electronic devices. This noise can travel through power lines or radiate through the air, affecting nearby equipment. It's like having a radio transmitter broadcasting static interference. Sensitive devices like PLCs (Programmable Logic Controllers) and instrumentation can be particularly vulnerable. Proper shielding and grounding are essential to minimize these problems.

So, before you go all-in on VFDs, consider the potential impact on your electrical system. Consult with an electrical engineer to assess your harmonic levels and determine if any mitigation measures are necessary. Ignoring these issues can lead to serious problems and costly repairs down the road. It's better to be safe than sorry, especially when dealing with electricity.

Motor Compatibility and Insulation Issues

3. Playing Nicely with Your Motor

Think you can just slap a VFD on any old motor and call it a day? Think again! Motor compatibility is a crucial factor to consider. Not all motors are created equal, and some might not be well-suited for VFD operation. Standard motors might not have adequate insulation to withstand the voltage spikes generated by a VFD. It's like trying to put racing tires on a family sedan — not a great fit.

The rapid switching of a VFD's output can cause voltage reflections and overvoltages at the motor terminals. This can lead to insulation breakdown and premature motor failure. Imagine tiny lightning bolts zapping your motor windings — that's essentially what's happening. Motors specifically designed for VFD operation, often called "inverter-duty" motors, have enhanced insulation to withstand these stresses. These are like motors wearing a super strong shield.

Even with inverter-duty motors, it's essential to use proper cabling and grounding techniques to minimize voltage reflections. Long cable runs between the VFD and the motor can exacerbate these problems. Think of it like shouting down a long hallway — the echo can distort your message. Using shielded cables and terminating them properly can help reduce these reflections and protect your motor's insulation.

Therefore, before connecting a VFD to a motor, check the motor's nameplate for its suitability for VFD operation. If you're unsure, consult with a motor manufacturer or an electrical engineer. Using the wrong motor can lead to costly repairs, downtime, and potentially hazardous conditions. It's always best to choose the right tools for the job.

Environmental Concerns and Sensitivity

4. Delicate Operation

Let's face it, VFDs aren't exactly built for harsh environments. While some are designed for tougher conditions, most are sensitive to things like excessive heat, dust, moisture, and vibration. Imagine leaving your laptop out in the rain — not a good idea, right? VFDs require a controlled environment to operate reliably. It's like having a race car — you want it running smoothly in a controlled environment to get the maximum performance.

High temperatures can cause overheating of the electronic components, leading to premature failure. Dust and dirt can accumulate on the heat sinks, reducing their cooling efficiency. Moisture can cause corrosion and short circuits. Vibration can loosen connections and damage sensitive components. It's like a domino effect — one problem can lead to many others. Enclosures and proper ventilation are crucial for protecting VFDs from these environmental hazards. You need to create a comfortable little home for it.

Extreme temperature fluctuations can also be problematic. Rapid changes in temperature can cause condensation to form inside the VFD, leading to corrosion and electrical failures. Maintaining a stable temperature is essential for long-term reliability. Think of it like storing fine wine — you need a consistent temperature to preserve its quality.

So, when planning your VFD installation, consider the environmental conditions. If you're operating in a harsh environment, you may need to invest in a more rugged VFD or provide additional protection. Ignoring these environmental factors can significantly reduce the lifespan of your VFD and lead to costly downtime. After all, you don't want your investment turning to dust before its time.

VFD Multiple Choice Questions Variable Frequency Drives

Troubleshooting and Expertise Requirements

5. When Things Go Wrong

Alright, let's be honest, sometimes things break. And when a VFD breaks, troubleshooting can be a bit of a headache. It's not like fixing a toaster. Diagnosing VFD problems often requires specialized knowledge and equipment. You can't just poke around with a screwdriver and hope for the best. It's more like solving a complex puzzle — you need the right tools and skills to figure it out.

VFDs are complex electronic devices with many internal components. Identifying the root cause of a problem can be challenging, especially if you're not familiar with the technology. You might need to use oscilloscopes, multimeters, and other specialized tools to diagnose the issue. It's like being a doctor — you need to use diagnostic tools to figure out what's wrong with your patient.

And it's not just the technical skills. You also need to understand the VFD's parameters, settings, and operating characteristics. This requires training and experience. Imagine trying to fly a plane without any flight training — it's not going to end well. Many companies rely on external experts for VFD troubleshooting and repairs. This can be costly, especially if you experience frequent problems.

Therefore, when considering VFDs, factor in the potential cost of troubleshooting and repairs. Having a qualified technician on staff or establishing a relationship with a reputable service provider can save you time and money in the long run. And, if you enjoy a challenge and are curious, taking some VFD training courses may be a great idea. It could save you a bundle in the long run!

FAQ Section

6. Frequently Asked Questions About VFD Disadvantages

Q: Are VFDs really worth the investment considering the disadvantages?

A: It depends! For applications requiring precise speed control and significant energy savings, VFDs are often a fantastic choice, despite the initial cost and potential maintenance. However, for simple on/off applications, a traditional motor starter might be more cost-effective. Think of it like choosing between a Swiss Army knife and a simple pocket knife. The Swiss Army knife is more versatile, but if you just need to open a letter, the pocket knife will do just fine. Carefully evaluate your specific needs before deciding.

Q: Can I prevent harmonic distortion caused by VFDs?

A: Absolutely! Harmonic filters are your best friend here. These devices help to reduce the amount of harmonic current injected into the power system. Also, using VFDs with built-in harmonic mitigation features can help. Regular electrical system audits can help detect harmonics before they become a big problem.

Q: What happens if I connect a standard motor to a VFD?

A: Risky move! Standard motors might not be able to handle the voltage stresses imposed by the VFD, potentially leading to insulation failure and premature motor burnout. It's like trying to run a marathon in flip-flops — you might start okay, but you'll likely end up with blisters and sore feet. It's always recommended to use inverter-duty motors designed for VFD operation.