Best Info About What Sensor Controls Throttle

Unlocking the Mystery

1. The Throttle's Puppet Master

Ever wondered what tells your engine how much "go" to give you? It's not magic, though sometimes it feels like it when you're cruising down the highway. The real brains behind the operation, the sensor that dictates how wide your throttle opens, is generally the Throttle Position Sensor (TPS). Think of it as the messenger between your gas pedal and your engine's desire for fuel and air. Without it, your engine would be clueless — and likely very unhappy.

This unassuming little sensor sits right on the throttle body, monitoring the position of the throttle plate. As you press the accelerator, the throttle plate pivots open, allowing more air to enter the engine. The TPS diligently reports this change in position back to the engine control unit (ECU), the car's main computer. The ECU then uses this information, along with data from other sensors, to calculate the precise amount of fuel needed for optimal combustion.

The elegance of the TPS lies in its simplicity and effectiveness. It's a variable resistor, meaning its resistance changes as the throttle plate moves. This change in resistance translates into a voltage signal that the ECU can understand. It's like a dimmer switch for your engine, but instead of controlling light, it's controlling power. This allows for smooth acceleration and efficient fuel consumption. Without this precise communication, you'd probably experience jerky acceleration, poor fuel economy, or even stalling.

Now, before you picture the TPS as some all-powerful overlord, it's important to remember that it works in concert with other sensors. The mass airflow sensor (MAF), for example, measures the amount of air entering the engine, providing crucial information for fuel mixture calculations. The engine coolant temperature sensor (ECT) tells the ECU how warm the engine is, influencing fuel enrichment during cold starts. Together, these sensors form a network of information that allows the ECU to manage the engine effectively.

:max_bytes(150000):strip_icc()/GettyImages-809095100-5a6f86ed0e23d90036769e6c.png)

How Electronic Throttle Control (ETC) Works

The Throttle Position Sensor (TPS) in Detail

2. Digging Deeper

Okay, so we know the TPS is important, but let's get a little more specific about how it actually works. Inside, it's usually a potentiometer, a type of variable resistor. As the throttle plate moves, it turns a shaft connected to the potentiometer's wiper arm. This wiper arm slides along a resistive track, changing the resistance and therefore the voltage signal sent to the ECU. The ECU interprets this voltage and adjusts the fuel injection accordingly. Pretty neat, huh?

Think of it like this: imagine a volume knob on an old radio. As you turn the knob, the resistance changes, affecting the loudness of the music. The TPS is similar, but instead of volume, it's controlling the amount of fuel injected into the engine. The more you press the accelerator, the wider the throttle opens, the higher the voltage signal, and the more fuel the ECU injects. It's all about precise control and efficient combustion.

The TPS is usually a three-wire sensor: one wire for power, one for ground, and one for the signal that communicates the throttle position to the ECU. If any of these wires are damaged or disconnected, the sensor won't function correctly, leading to problems like poor acceleration, stalling, or even a check engine light. So, if you're experiencing any of these symptoms, it's worth checking the TPS and its wiring harness.

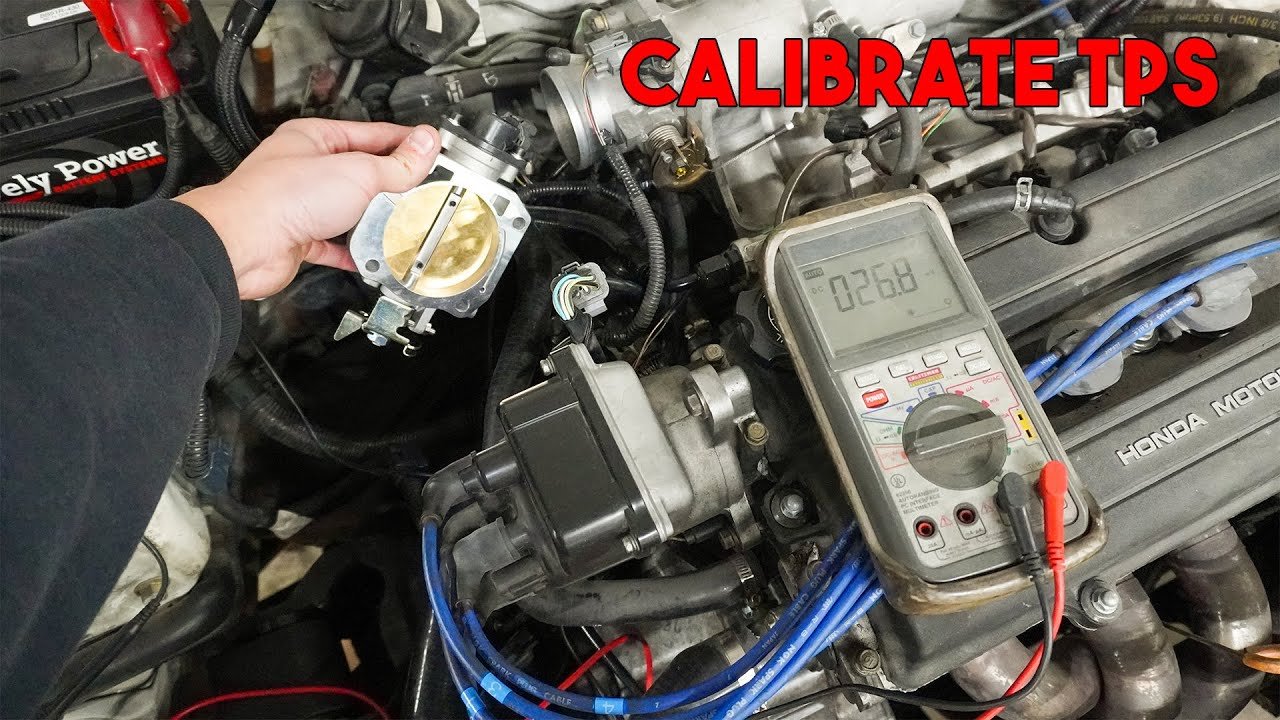

Also, the TPS needs to be properly calibrated. Sometimes, after replacing a TPS, you'll need to use a scan tool to tell the ECU the correct voltage range for the sensor. This ensures that the ECU accurately interprets the throttle position and provides the right amount of fuel. If the TPS isn't calibrated correctly, you might experience erratic engine behavior or poor performance.

What Does A Throttle Sensor Do Bogados

Symptoms of a Failing Throttle Position Sensor

3. Warning Signs

So how do you know if your TPS is on its way out? Well, thankfully, your car usually gives you some warning signs. Keep an eye (and ear) out for these common symptoms of a failing TPS. One of the most common indicators is erratic idling. Your engine might idle too high, too low, or even fluctuate up and down. It's like your car is having a hard time deciding how much power it needs when you're stopped.

Another symptom is poor acceleration. Your car might feel sluggish or hesitant when you press the gas pedal. It's like trying to run a race with your shoes tied together. The engine isn't getting the right amount of fuel, so it can't accelerate smoothly. You might also experience stumbling or stalling, especially when accelerating from a stop. This is because the ECU isn't getting accurate information about the throttle position, so it can't adjust the fuel mixture correctly.

Keep a watch for inconsistent shifting. If you have an automatic transmission, you might notice that the gears are shifting at the wrong times or that the transmission is shifting harshly. This is because the ECU uses throttle position information to control the transmission, and a faulty TPS can throw things off. And, of course, the dreaded check engine light. A faulty TPS will often trigger a diagnostic trouble code (DTC), which will illuminate the check engine light. So, if you see that light come on, it's worth getting your car scanned for codes.

If you're experiencing any of these symptoms, don't ignore them. A failing TPS can eventually lead to more serious engine problems. It's best to get it checked out by a qualified mechanic as soon as possible. They can diagnose the problem and replace the TPS if necessary, restoring your engine's smooth operation and fuel efficiency.

Symptoms Of A Bad Throttle Position Sensor

Diagnosing and Replacing a Faulty TPS

4. Taking Action

Alright, let's say you suspect your TPS is acting up. What's the next step? Diagnosing a TPS typically involves using a multimeter to check the sensor's voltage output. You'll need to consult your car's repair manual for the specific voltage ranges for your particular model. A good mechanic can test the TPS at different throttle positions to see if the voltage changes smoothly and consistently. If the voltage is erratic or doesn't change as expected, the TPS is likely faulty.

You can also use a scan tool to read the TPS voltage. This can give you a more accurate reading than a multimeter and can also help you identify any diagnostic trouble codes (DTCs) related to the TPS. The scan tool will show the live data stream from the TPS, allowing you to see how the voltage changes as you press the gas pedal.

Replacing a TPS is usually a pretty straightforward job, but it's important to follow the correct procedures. First, disconnect the negative battery cable to prevent any electrical accidents. Then, locate the TPS on the throttle body and unplug its electrical connector. Remove the mounting screws and carefully remove the old TPS. Install the new TPS, making sure it's properly aligned. Then, tighten the mounting screws and reconnect the electrical connector. Finally, reconnect the negative battery cable.

As mentioned earlier, some TPSs require calibration after replacement. Use a scan tool to calibrate the new TPS, following the manufacturer's instructions. This ensures that the ECU accurately interprets the throttle position. After replacing and calibrating the TPS, clear any diagnostic trouble codes and take your car for a test drive. Hopefully, the symptoms you were experiencing are now gone, and your engine is running smoothly again.

Throttle Position Sensor Explained

Other Sensors Influencing Throttle Behavior

5. The Bigger Picture

While the TPS is the direct controller of the throttle plate, it's not acting in isolation. Several other sensors contribute to the overall throttle behavior and engine performance. We've already mentioned the MAF sensor, which measures the amount of air entering the engine. The ECU uses this information to calculate the correct air-fuel ratio. If the MAF sensor is faulty, it can cause the engine to run lean or rich, leading to poor performance and fuel economy. It's like having a chef who can't accurately measure ingredients.

The oxygen sensors (O2 sensors) in the exhaust system provide feedback to the ECU about the oxygen content in the exhaust gases. This information helps the ECU fine-tune the air-fuel mixture for optimal combustion. If the O2 sensors are faulty, the ECU might not be able to accurately adjust the fuel mixture, leading to poor performance, increased emissions, and even damage to the catalytic converter. Think of them as the taste testers for your engine, ensuring the recipe is just right.

The engine coolant temperature sensor (ECT) tells the ECU how warm the engine is. During cold starts, the ECU enriches the fuel mixture to help the engine start and run smoothly. As the engine warms up, the ECU gradually leans out the fuel mixture. If the ECT is faulty, it can cause hard starting, poor fuel economy, and rough idling. The MAP sensor is crucial for calculating air density.

Finally, the crankshaft position sensor (CKP) and camshaft position sensor (CMP) are essential for determining the engine's speed and position. This information is used to control ignition timing and fuel injection. If either of these sensors is faulty, it can cause the engine to misfire, stall, or even fail to start. These sensors are the heartbeats of your engine, providing crucial timing information to the ECU.