Lessons I Learned From Tips About What Is The Difference Between SC And LC SFP

SC vs. LC SFP

1. Decoding the Acronyms

Ever stared at the back of a network switch and felt a wave of alphabet-soup-induced dizziness? You're not alone! Among the many TLAs (Three-Letter Acronyms) you might encounter, SC and LC often pop up, especially when dealing with SFPs (Small Form-factor Pluggables). These little guys are essential for connecting fiber optic cables to your network gear, but understanding the difference between SC and LC can be a bit well, confusing. Let's demystify them, shall we? Think of it as learning a new language, but instead of conjugating verbs, you're plugging in cables. Much less stressful, right?

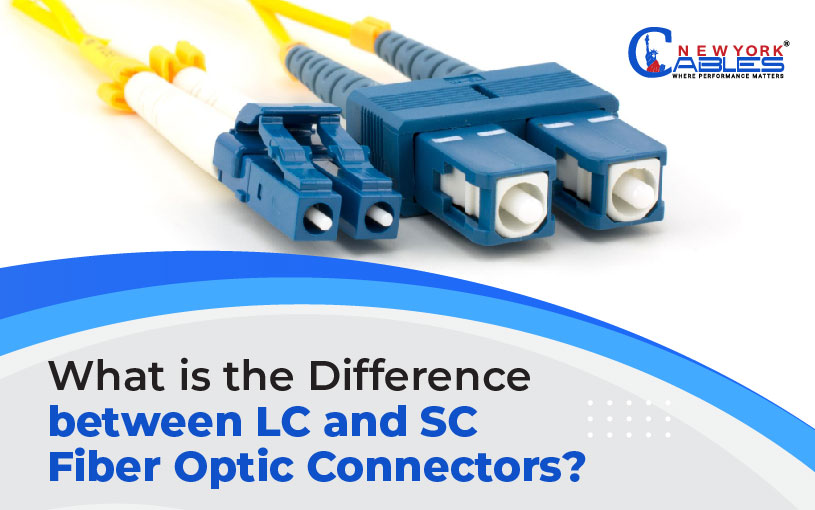

The fundamental difference between SC and LC lies primarily in their connector design. SC stands for "Subscriber Connector" or sometimes "Standard Connector." It's an older design, recognizable by its square, push-pull latching mechanism. Imagine a little square box that clicks into place. That's your SC connector. LC, on the other hand, stands for "Lucent Connector" (named after Lucent Technologies, now part of Nokia). It's a smaller, more compact design with a tabbed latch, similar to an RJ45 connector (the kind you use for Ethernet cables). Think of it as the more modern, space-saving option.

Now, before you ask, no, you can't just jam an SC connector into an LC port or vice versa. They're physically incompatible. Trying to force it will likely result in damage to the connector or the port — and nobody wants that expensive repair bill. Think of it like trying to fit a square peg in a round hole. It just doesn't work, no matter how hard you push (please don't push!).

So, which one is "better"? Well, it depends. Both SC and LC connectors serve the same basic purpose: to provide a reliable connection for transmitting data over fiber optic cables. The choice often comes down to factors like port density (how many connections you can fit in a given space), cost, and existing infrastructure. For newer installations, LC is often preferred due to its smaller size and higher port density capabilities. But SC still has its place, particularly in older systems or where robustness and ease of use are prioritized.

Size Matters (and So Does Port Density)

2. The Compact Advantage

Let's talk about size, because in the world of networking, real estate is precious. LC connectors are significantly smaller than SC connectors. This might not seem like a big deal, but when you're dealing with high-density environments where you need to pack a lot of connections into a limited space, that size difference becomes crucial. Imagine trying to fit all your shoes into a tiny apartment closet — every inch counts!

The smaller size of LC connectors allows for higher port density on network devices. This means you can fit more LC ports on a single switch or router compared to SC ports. Think of it like upgrading from a compact car to a motorcycle. You can fit way more motorcycles in the same parking spot as cars. More ports mean more connections, which is always a good thing (unless you're also responsible for managing all those connections, then maybe it's a mixed blessing).

This higher port density translates to significant cost savings in the long run. By using LC connectors, you can often reduce the number of switches or routers needed to support a given number of connections, which saves on hardware costs, power consumption, and rack space. It's like buying a bulk pack of your favorite snack — you save money and have more to go around.

However, it's worth noting that the smaller size of LC connectors can also make them slightly more fragile than SC connectors. They're also a bit more fiddly to work with, especially for those with larger fingers. It's a trade-off between size, density, and robustness. So, consider your environment and needs when making your decision. Are you working in a data center where every inch counts, or in a rugged environment where durability is paramount?

Performance and Cost

3. Beyond the Physical Differences

While the physical size and port density are key differentiators, what about performance and cost? In terms of raw performance, both SC and LC connectors are capable of supporting high-speed data transmission. The choice of connector doesn't typically have a significant impact on the speed or quality of the signal. Think of it like different brands of gasoline — they all fuel your car, but some might offer slightly better mileage or performance.

However, the cost can vary depending on the specific type of SFP module and the connector used. Generally, LC connectors and SFPs tend to be slightly more expensive than their SC counterparts, primarily due to the more complex manufacturing process involved in creating the smaller LC connector. It's like comparing a handcrafted coffee to a regular drip coffee — the handcrafted one usually costs more due to the extra effort and skill required.

But again, the overall cost savings from higher port density can often outweigh the slightly higher cost per LC connector. So, it's important to consider the total cost of ownership, including hardware costs, power consumption, rack space, and maintenance. Don't just focus on the initial price tag — look at the bigger picture.

Finally, consider the existing infrastructure. If you already have a network that's primarily based on SC connectors, switching to LC might require replacing a significant amount of cabling and equipment, which can be a costly and time-consuming endeavor. It's like renovating your entire house — it can be a huge undertaking. In such cases, sticking with SC might be the more practical and cost-effective option.

LC Vs SC MU Connectors What Is The Difference?

Practical Applications

4. Matching the Connector to the Task

Now that we've covered the technical details, let's talk about where SC and LC connectors are typically used in real-world scenarios. SC connectors are often found in older networking equipment and in applications where robustness and ease of use are more important than port density. Think of them as the reliable workhorses of the fiber optic world.

You might find SC connectors in environments like industrial settings, where equipment is exposed to harsh conditions and where ease of connection is crucial for quick repairs or maintenance. They're also commonly used in older telecommunications infrastructure. They are known to be durable and reliable, but are less common in cutting-edge, modern data centers.

LC connectors, on the other hand, are the preferred choice for modern data centers, enterprise networks, and other high-density environments. Their smaller size allows for more ports per device, which is essential for supporting the growing demands of today's bandwidth-intensive applications. They're like the sleek sports cars of the fiber optic world, optimized for speed and performance.

So, when you're choosing between SC and LC, consider the specific requirements of your application. Are you building a new data center from scratch? LC is likely the way to go. Are you upgrading an existing network with older equipment? SC might be the more practical option. It's all about finding the right tool for the job.

Making the Right Choice

5. Choosing What's Right for You

Okay, so we've thrown a lot of information at you. Let's recap the key differences between SC and LC SFPs to help you make the right choice for your network needs. Remember, it's not about which one is "better" in an absolute sense, but rather which one is better suited for your specific situation.

SC connectors are larger, more robust, and generally easier to use, making them a good choice for older equipment, industrial environments, and applications where durability is paramount. LC connectors are smaller, allowing for higher port density, making them ideal for modern data centers, enterprise networks, and other high-density environments. And while LC connectors tend to be slightly more expensive upfront, the overall cost savings from higher port density can often outweigh the initial price difference.

Ultimately, the best way to decide is to carefully assess your network requirements, consider your budget, and evaluate your existing infrastructure. Don't be afraid to consult with a networking professional if you're unsure. They can help you analyze your needs and recommend the best solution for your specific situation. Think of them as your fiber optic gurus, guiding you through the maze of connectors and cables.

And remember, no matter which connector you choose, always use high-quality cables and SFPs to ensure reliable performance and avoid costly downtime. A cheap cable might seem like a good deal at first, but it can end up costing you more in the long run. It's like buying a cheap pair of shoes — they might fall apart after a few weeks. Investing in quality is always a good idea!