One Of The Best Tips About What Are The Three Basic Types Of Controllers

![PS4 Controller Buttons Names/Layout/Functions [Full Guide] MiniTool PS4 Controller Buttons Names/Layout/Functions [Full Guide] MiniTool](https://www.partitionwizard.com/images/uploads/articles/2022/11/ps4-controller-buttons/ps4-controller-buttons-1.png)

Understanding the World of Controllers

1. Diving into the Controller Universe

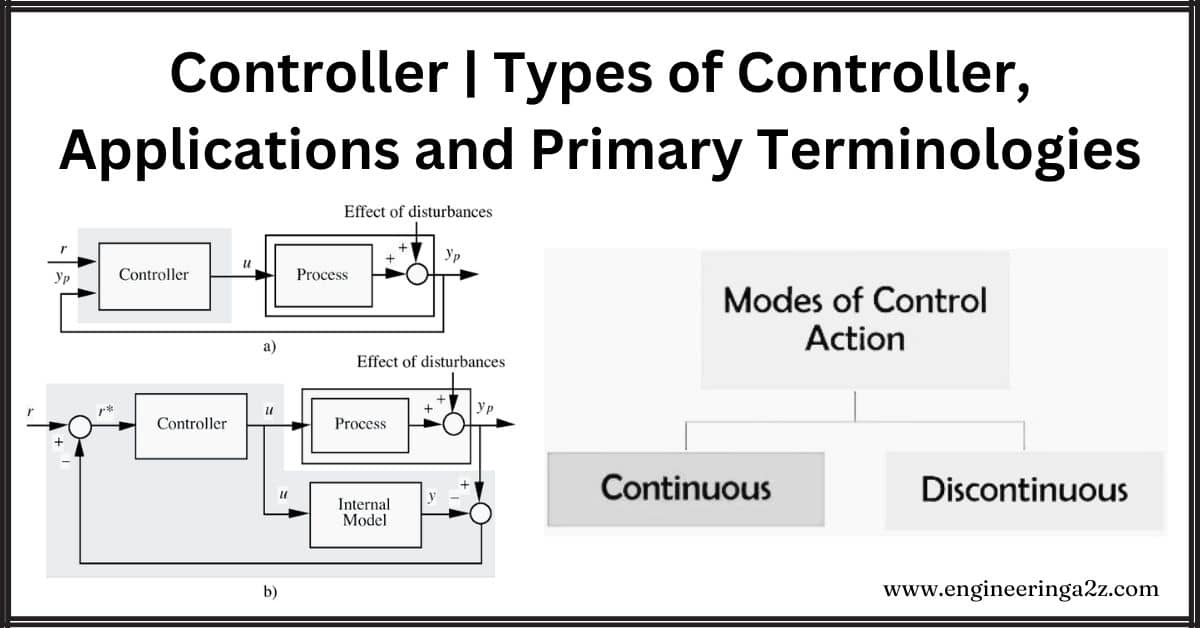

Okay, so when you hear "controller," your mind probably jumps straight to gaming, right? Xbox, PlayStation, maybe even a fancy flight simulator joystick. But the truth is, controllers are everywhere, silently working behind the scenes to make our lives easier — or at least, more controlled! We're not just talking button-mashing devices here; we're venturing into a realm where technology empowers us to manage everything from temperature to enormous industrial machinery. Prepare for a revelation: control is all around us!

Think about it: your thermostat, your car's cruise control, even the robotic arm on a factory assembly line — all these things rely on controllers to function. These devices aren't just about on and off; they fine-tune processes, make adjustments based on feedback, and generally prevent chaos from erupting. So, let's peel back the layers and explore the fundamental types of controllers that make our tech-driven world tick.

In this article, we're going to look beyond the joysticks and D-pads to uncover the three core types of controllers. Well delve into how they operate and the role they play in both simple everyday tasks and more complex, high-tech applications. Forget the idea that these are dry, technical components — they're actually fascinating pieces of engineering that enable some pretty impressive feats!

So, buckle up! Whether you're a curious student, a budding engineer, or just someone who likes to know how things work, you're about to embark on a surprisingly engaging journey into the heart of control. Let's get started and demystify the world of controllers!

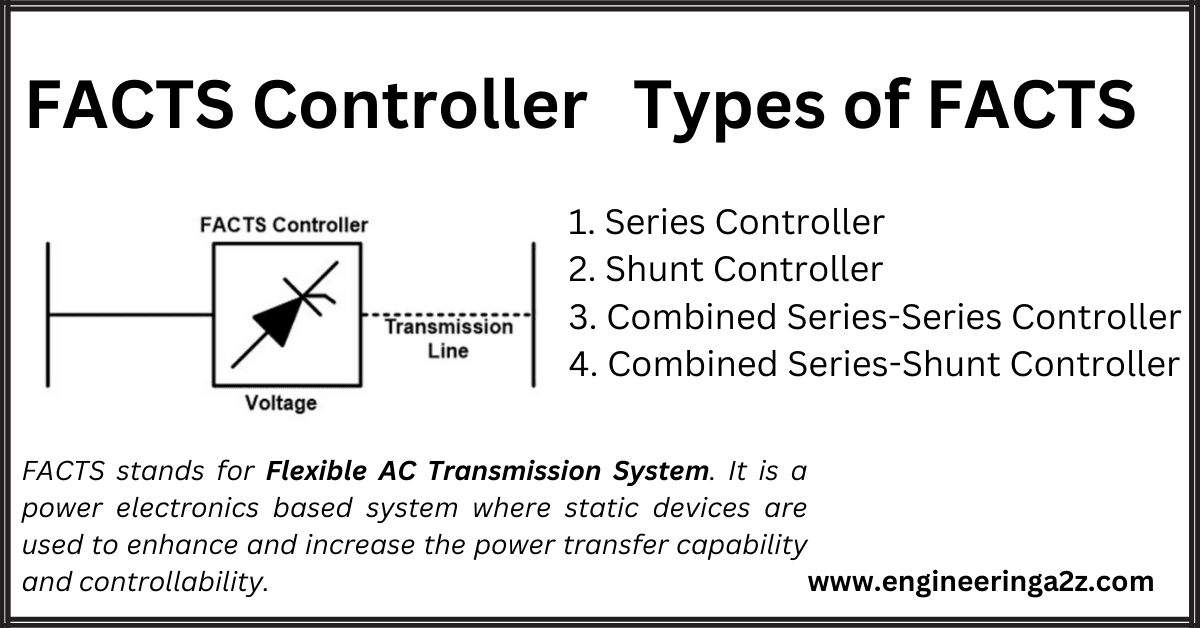

FACTS Controller Types Of

The Trio of Control

2. On-Off (or Bang-Bang) Controllers

Let's start with the simplest type: the On-Off controller. It's exactly what it sounds like — it only has two states: on or off. Imagine your trusty old kettle. When the water temperature dips below a certain point, the heating element switches on. When the water boils, it switches off. Simple, right? These are the reliable workhorses of the control world.

Think of it like this: you're trying to maintain the temperature of your swimming pool. An On-Off controller would just blast the heater on until the water hits your desired temperature, then shut it off completely. It's not the most elegant solution, but it's often cheap and effective, perfect for applications where precise temperature control isn't crucial. It does the job, even if its not winning any awards for finesse.

Now, you might be thinking, "Isn't that a bit...clunky?" And you'd be right! On-Off controllers often lead to something called "overshoot," where the controlled variable (like temperature) swings wildly around the set point. That's because there's no gradual adjustment — it's either full power or nothing. However, for many applications, the simplicity and low cost outweigh the lack of precision.

So, if you need a straightforward, no-frills solution and precise control isn't a top priority, the On-Off controller might just be your best bet. Don't underestimate its power! It may be simple, but its reliable and can handle many essential tasks perfectly well. Its like the hammer in your toolbox — not fancy, but indispensable.

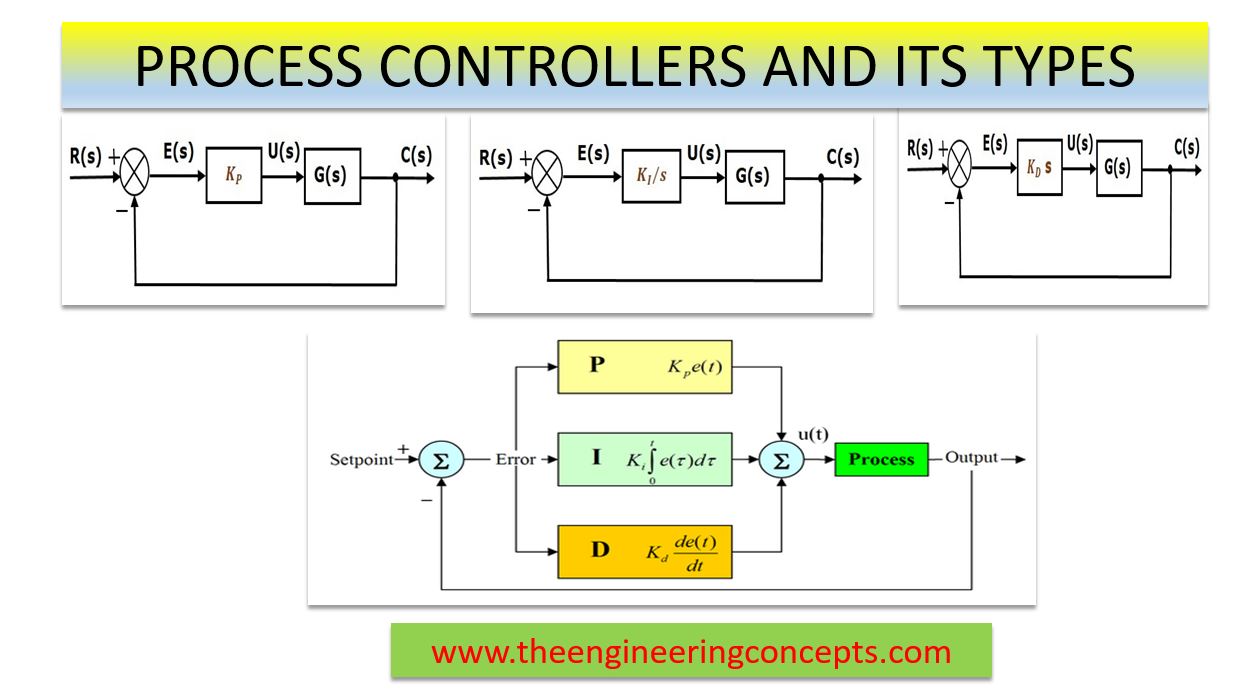

PROCESS CONTROLLERS AND ITS TYPES The Engineering Concepts

Proportional (P) Controllers

3. Fine-Tuning Control with Proportional Action

Next up, we have Proportional (P) controllers. These controllers offer a more refined level of control compared to their On-Off counterparts. Instead of simply switching between on and off, P controllers adjust the output based on the difference between the desired value (the setpoint) and the actual value (the process variable). The bigger the difference, the stronger the corrective action.

Imagine driving a car with cruise control. A P controller would smoothly adjust the throttle based on how far below or above your set speed you are. If you're lagging behind, it gently increases the throttle; if you're going too fast, it eases off. This continuous adjustment helps to maintain a much more stable speed than you'd get with an On-Off system. This is all about proportional response to change.

Now, theres a catch: P controllers often suffer from what's called "offset." This means that the process variable might not perfectly reach the setpoint, but instead settle slightly below it. It's like trying to perfectly balance a scale — you might get close, but there's always a slight imbalance. This is often because the controller doesn't provide enough power to completely eliminate the error.

Despite the offset issue, P controllers offer a significant improvement over On-Off controllers in terms of stability and responsiveness. They're used in applications where smoother, more gradual adjustments are needed, like controlling the temperature in a greenhouse or regulating the flow of liquid in a chemical process. It's all about getting a bit more sophisticated and precise in your control strategy.

PID Controllers

4. The Ultimate in Precision

Finally, we arrive at the king of the hill: the PID controller. PID stands for Proportional, Integral, and Derivative. This type of controller combines the best of both worlds — the responsiveness of a P controller, the ability to eliminate offset with an I controller, and the predictive power of a D controller. It's the ultimate in precision and control, like the brain surgeon of the controller world.

Think of it this way: the Proportional part responds to the current error, just like in a P controller. The Integral part looks at the accumulated error over time and adjusts the output to eliminate any remaining offset. And the Derivative part anticipates future error by looking at the rate of change of the error. It's like having a crystal ball that allows the controller to predict what's going to happen next and take corrective action accordingly. Its predictive and corrective!

Let's say you're controlling the temperature of a high-precision incubator. The PID controller would use the P term to quickly respond to any deviations from the setpoint. The I term would gradually eliminate any offset, ensuring that the temperature stays perfectly at the desired level. And the D term would anticipate any sudden temperature fluctuations and adjust the heating element accordingly, preventing overshoot and maintaining a stable temperature. It's a symphony of control!

PID controllers are used in a wide range of applications where precise and stable control is essential, such as chemical plants, robotics, and aerospace engineering. They're complex beasts to tune and configure, but when done right, they can achieve remarkable levels of performance. Mastering the PID controller is akin to mastering the art of control itself. It is the apex of precision, adaptability, and responsiveness.

What Is The Magic Of PS4 Controller? PCBA Makers

Choosing the Right Controller

5. Making the Right Choice for Your Needs

So, how do you choose the right controller for your specific application? Well, it all comes down to the requirements of the job. If you need a simple, low-cost solution and precise control isn't critical, an On-Off controller might be the perfect choice. Its uncomplicated and reliable.

If you need more precise control and responsiveness, but can tolerate a small amount of offset, a Proportional controller might be a better option. It provides smoother adjustments than an On-Off controller, but it's still relatively simple to implement. It's a solid middle ground for many applications.

And if you need the ultimate in precision and stability, a PID controller is the way to go. However, be prepared to invest the time and effort required to properly tune and configure it. It's the most complex of the three, but the results can be well worth the effort. It's perfect when failure isnt an option.

Ultimately, the best controller is the one that meets your specific needs in terms of performance, cost, and complexity. Understanding the strengths and weaknesses of each type will help you make an informed decision and achieve the desired level of control in your application. Consider the potential consequences of failure. That will really clarify the best choice. Consider your own skills and whether youll require expert help.

FAQs

6. Your Questions Answered

Got some burning questions about controllers? Let's tackle a few of the most common ones!

Q: Are there other types of controllers besides these three?A: Absolutely! These are just the basic types. There are many variations and combinations, such as fuzzy logic controllers, adaptive controllers, and model predictive controllers. But understanding these three is a great foundation.

Q: What's the hardest part about using PID controllers?A: Tuning them! Getting the P, I, and D values just right can be tricky and often requires experimentation or specialized software. Badly tuned PID controllers can actually make things worse, leading to oscillations or instability.

Q: Where can I learn more about control systems?A: There are tons of resources online, including textbooks, websites, and online courses. Search for "control systems engineering" or "process control" to find a wealth of information. Your local community college or university likely has classes too!