One Of The Best Tips About Can We Use IGBT Instead Of MOSFET

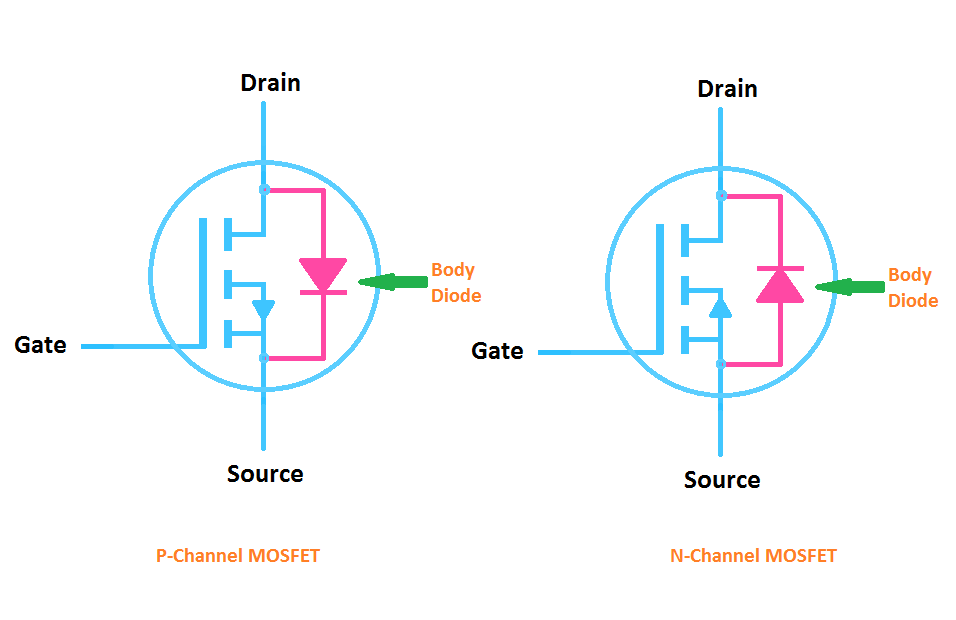

Why Diode Is Connected Across IGBT And MOSFET? Body Or Intrinsic

IGBT vs. MOSFET

1. Understanding the Contenders

So, you're pondering a serious question: Can we use an IGBT instead of a MOSFET? Well, buckle up, because we're diving into the electrifying world of power electronics! These two little components, the Insulated Gate Bipolar Transistor (IGBT) and the Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET), are essentially tiny electronic switches. They control the flow of power in a vast array of applications, from your electric car to the hum of your refrigerator. But here's the kicker: they each have their strengths and weaknesses.

Think of it like this: Imagine you're trying to decide between a nimble sports car (the MOSFET) and a heavy-duty pickup truck (the IGBT). The sports car is quick and agile, great for zipping around town. The pickup truck? It can haul a ton of bricks, but it's not exactly winning any races. The right choice depends entirely on the job you need to do.

Now, let's get a little more technical without drowning in jargon. MOSFETs are known for their fast switching speeds. They can turn on and off incredibly quickly, making them ideal for applications where high frequency is key, like power supplies in your computer. On the other hand, IGBTs are the powerhouses. They can handle much higher voltages and currents than MOSFETs, making them suitable for high-power applications like motor control in electric vehicles or industrial welding machines. They don't switch as fast as MOSFETs, but they can withstand a whole lot more abuse.

In essence, the choice between an IGBT and a MOSFET isn't about one being "better" than the other. It's about understanding their individual characteristics and choosing the right tool for the specific task at hand. It's like choosing the right wrench for the job. A tiny wrench is useless for a big bolt and vice versa.

Igbt Vs Mosfet Welding Machine

Decoding the Differences

2. Key Performance Indicators

Okay, let's break down the main differences between IGBTs and MOSFETs in a way that's, dare I say, almost fun. Think of voltage as the pressure of the water in a pipe, and current as the amount of water flowing through it. An IGBT can handle a much higher pressure and a greater volume of water (high voltage and high current) than a MOSFET. But that MOSFET? It can open and close the valve (switch) much faster.

Let's get a bit more precise, shall we? MOSFETs typically excel in applications up to a few hundred volts. Above that voltage, IGBTs start to shine. In terms of current, MOSFETs are great for applications that require a few amps, or maybe a few dozen. IGBTs, however, can handle hundreds, even thousands, of amps. That's serious power!

Now, switching speed. This is where MOSFETs truly take the lead. They can switch on and off in nanoseconds (billionths of a second). IGBTs, on the other hand, are a bit slower, switching in microseconds (millionths of a second). While that might not seem like a huge difference, it can be critical in high-frequency applications.

Here's a simple rule of thumb: If you're dealing with relatively low voltage and current, and high switching speeds are important, a MOSFET is likely your best bet. If you need to handle high voltage and high current, and switching speed isn't the primary concern, an IGBT will probably be a better fit. It's a bit like choosing between a cheetah and an elephant — both are amazing animals, but they excel in different environments.

When to Choose an IGBT Over a MOSFET (And Vice Versa)

3. Practical Applications and Trade-offs

Let's talk real-world scenarios. Imagine you're designing a variable frequency drive (VFD) for a large industrial motor. These motors often operate at high voltages, and the VFD needs to control a significant amount of current. In this case, an IGBT would be the obvious choice. It can handle the high voltage and current demands of the motor, ensuring smooth and reliable operation.

Now, let's say you're designing a power supply for a laptop computer. Here, size, efficiency, and switching speed are all critical. A MOSFET would be a much better option. It can switch at high frequencies, allowing for a smaller and more efficient power supply. Plus, laptops typically operate at lower voltages, so the MOSFET's voltage limitations aren't a concern.

There are some areas where the choice isn't quite so clear-cut. For example, in some electric vehicle applications, both IGBTs and MOSFETs are used. IGBTs might be used in the main traction inverter, where high power handling is essential, while MOSFETs might be used in auxiliary circuits, where high switching speed is more important.

Ultimately, the decision comes down to carefully considering the specific requirements of your application and weighing the trade-offs between voltage, current, switching speed, cost, and other factors. It's about finding the sweet spot where the chosen component performs optimally without breaking the bank. Don't just pick one because it sounds cooler, do your research!

IGBT Vs MOSFET Difference And Comparison

The Future of Power Electronics

4. Emerging Technologies and Trends

The world of power electronics is constantly evolving, with new technologies and materials emerging all the time. Wide-bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are becoming increasingly popular. These materials offer significant advantages over traditional silicon-based devices, including higher voltage capabilities, faster switching speeds, and improved efficiency.

SiC MOSFETs, for example, are gaining traction in electric vehicle applications. They offer a combination of high voltage capability and fast switching speed, allowing for more efficient and compact power converters. GaN transistors are also being used in power supplies and other applications where high efficiency and small size are critical.

While WBG semiconductors are promising, they're still relatively expensive compared to traditional silicon-based devices. As the technology matures and production volumes increase, the cost is expected to come down, making them more accessible for a wider range of applications. This could blur the lines between applications suited for IGBTs and MOSFETs even further, creating even more flexible design options.

The future of power electronics is bright, with continuous innovation pushing the boundaries of what's possible. Whether you're working with IGBTs, MOSFETs, or emerging WBG technologies, understanding the fundamental principles and trade-offs is essential for designing efficient and reliable power electronic systems. Keep learning, keep experimenting, and keep pushing the boundaries of what's possible!

Why Would You Ever Use A MOSFET Over An IGBT? Either

Frequently Asked Questions (FAQs)

5. Your Burning Questions Answered

Alright, let's tackle some common questions that might be swirling around in your brain. You might be thinking, "This is all interesting, but what about..."

Q: Can I just use an IGBT for everything to be safe?

A: While IGBTs can handle a lot of power, using them in low-power, high-frequency applications where MOSFETs excel would be like using a sledgehammer to crack a nut. You'll lose efficiency, generate more heat, and potentially increase the size and cost of your system. It's always best to choose the right tool for the job!

Q: Are IGBTs always more expensive than MOSFETs?

A: Generally speaking, IGBTs are more expensive than MOSFETs, especially at lower voltage and current ratings. However, the cost difference can vary depending on the specific components and quantities involved. For very high-power applications, the IGBT might actually be the more cost-effective choice because a MOSFET solution could require paralleling many devices which adds complexity and cost.

Q: What about heat dissipation? Do IGBTs or MOSFETs run cooler?

A: It's not so much about which runs cooler intrinsically, but rather which one dissipates less power in a given application. Because MOSFETs switch so quickly, they generally have lower switching losses in high-frequency applications than IGBTs, and therefore generate less heat. However, if you tried to run a MOSFET at the same voltage and current as an IGBT designed for it, that MOSFET would probably fail spectacularly and generate a lot of heat, briefly! So, it's very application dependent.

Q: Where can I learn more about designing with IGBTs and MOSFETs?

A: There are tons of resources available online, including datasheets, application notes, and tutorials. Semiconductor manufacturers like Infineon, ON Semiconductor, and STMicroelectronics offer a wealth of information on their websites. You can also find helpful communities and forums where engineers share their knowledge and experience. And don't forget to check out online courses and university resources for more in-depth learning!