Great Info About How To Connect A Wire Connection

Making the Right Connection

1. Understanding the Basics Before You Start

So, youre staring at a couple of wires and maybe a terminal block, and you need to join them together. Don't sweat it! Connecting wires isn't rocket science, but getting it right is pretty important. Were talking safety, reliability, and avoiding that dreaded electrical hum. Think of it like baking a cake—follow the recipe (or in this case, the steps), and youll end up with a sweet result.

Before you even think about grabbing your tools, lets talk safety. Electricity is like a grumpy cat—it can bite if you're not careful. Always, always turn off the power at the breaker box before you start working on any electrical project. Double-check it with a non-contact voltage tester just to be absolutely sure. It's better to be safe than sorry...or shocked!

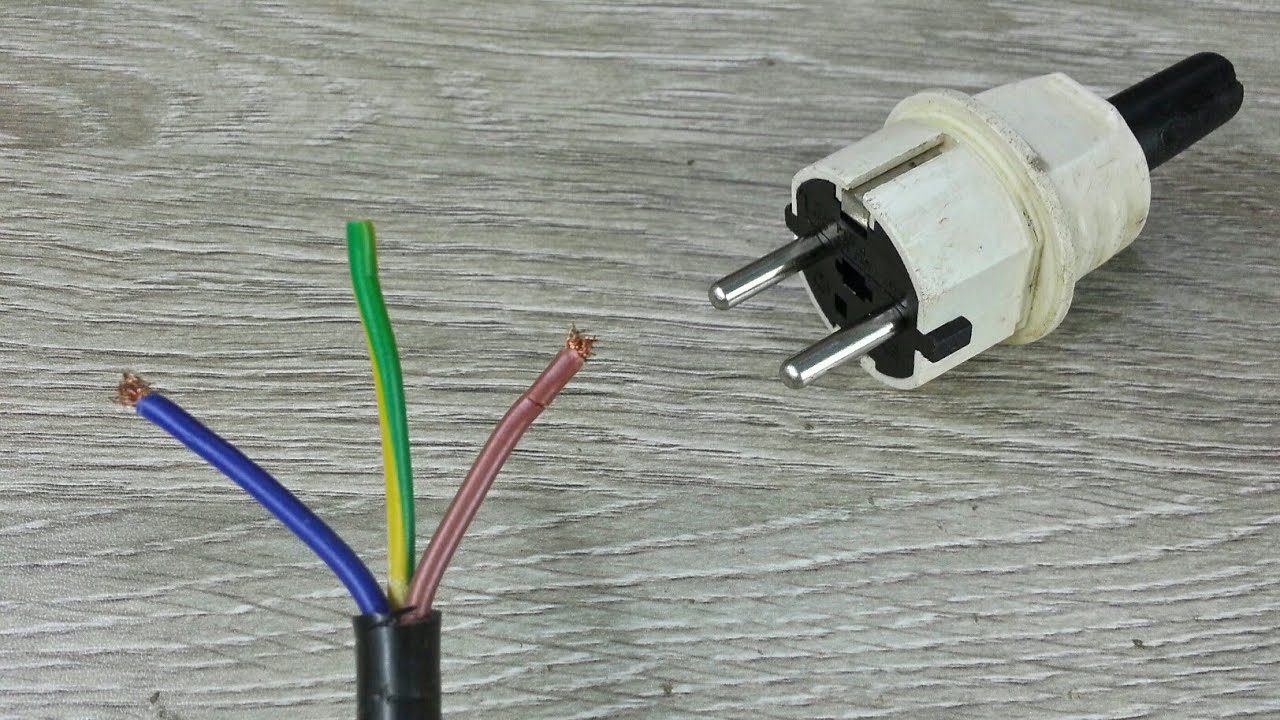

Next, identify the type of wires youre dealing with. Are they solid or stranded? What gauge are they (the thickness)? This information will help you choose the right tools and techniques. Imagine trying to use a tiny screwdriver on a giant screw—it's just not going to work. So, do your homework and make sure you have the right equipment for the job.

Finally, consider the environment. Is it a dry indoor space or a damp outdoor one? The location will influence the type of connectors you use. You wouldn't wear sandals in a snowstorm, would you? Similarly, you need to choose connectors that are appropriate for the conditions. Weatherproof connectors are your friends in damp or outdoor settings.

Stripping Wires Like a Pro (Without Damaging Them!)

2. The Art of the Wire Stripper

Stripping the insulation off a wire is a crucial step. Too much insulation left on, and the connection won't be good. Too little, and you risk exposing too much bare wire, which could lead to shorts. It's a delicate balance, like walking a tightrope...but with less falling (hopefully!).

The most common tool for this is, unsurprisingly, a wire stripper. These come in various forms, from simple manual ones to fancy automatic ones. Choose one that's comfortable for you to use and that matches the gauge of the wires you're working with. Using the wrong size can damage the wire, which defeats the whole purpose.

When stripping, gently squeeze the wire stripper and rotate it around the wire. Then, pull the insulation off in a smooth, even motion. Avoid nicking or cutting the wire itself. Those little nicks are like tiny stress fractures—they can weaken the wire and eventually lead to a break.

Aim to strip about 3/4 of an inch of insulation off the wire. This gives you enough bare wire to make a secure connection, but not so much that its dangling around like a loose thread. Practice makes perfect, so don't be discouraged if you mess up a few times. We've all been there!

Connect Wires To Outlet

Choosing the Right Connector

3. Navigating the Connector Jungle

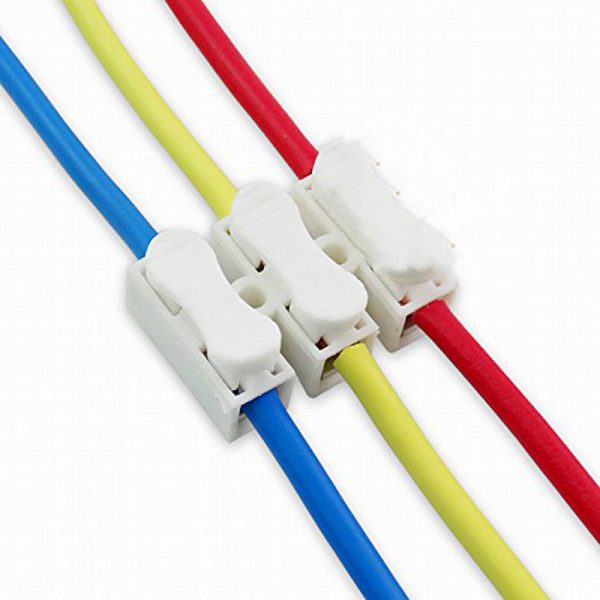

Ah, the world of wire connectors! It's a vast and sometimes confusing landscape. But fear not, we'll guide you through the jungle. The type of connector you choose will depend on the application, the size of the wires, and your personal preference. Its like choosing between pizza and tacos—theres no single best option, just whats right for you (and the situation!).

Wire nuts are probably the most common type of connector. Theyre simple to use and relatively inexpensive. Just twist the bare ends of the wires together, then screw the wire nut on. Make sure the wires are twisted tightly together before you put the nut on, or you might end up with a loose connection. Imagine trying to hold a bunch of slippery noodles together—you need a firm grip!

Terminal blocks are another popular option, especially for connecting multiple wires to a device. They provide a secure and organized way to make connections. Simply insert the bare wire into the terminal and tighten the screw. Again, make sure the wire is fully inserted and the screw is tight, but don't overtighten, or you could damage the terminal. It's all about finding that "just right" Goldilocks zone.

For more demanding applications, you might consider using crimp connectors. These require a special crimping tool to create a secure, gas-tight connection. Crimp connectors are often used in automotive and marine applications, where reliability is critical. They're like the duct tape of the electrical world—strong, reliable, and versatile.

How To Connect Wires Electrical Outlet

Making the Connection

4. Putting it All Together

Alright, we've covered the basics, now lets get down to the actual connection. The exact steps will vary depending on the type of connector you're using, but heres a general overview. Think of it like following a dance routine—each step builds upon the last.

For wire nuts, start by twisting the bare ends of the wires together in a clockwise direction. Use pliers if necessary to get a tight, even twist. Then, push the wire nut over the twisted wires and twist it until it's snug. Give it a gentle tug to make sure the connection is secure. If the wires come loose, start over.

For terminal blocks, insert the bare wire into the terminal opening and tighten the screw. Use a screwdriver that fits the screw head properly. Again, don't overtighten the screw. A good rule of thumb is to tighten it until it's snug, then give it another quarter turn. This will ensure a good connection without damaging the terminal.

With crimp connectors, insert the bare wire into the connector and use the crimping tool to crimp it tightly. Make sure you use the correct size crimping die for the connector you're using. A proper crimp should be strong and secure. You can usually tell a good crimp by its appearance—it should look uniform and well-compressed.

Testing and Securing Your Work

5. Ensuring a Safe and Reliable Connection

Once you've made the connection, its important to test it to make sure it's working properly. This is especially important for electrical circuits. You wouldnt serve a cake without tasting it first, would you? Similarly, you shouldn't power up a circuit without testing the connections.

Use a multimeter to check for continuity and voltage. Continuity testing ensures that the circuit is complete and that there are no breaks in the wiring. Voltage testing ensures that the correct voltage is present at the connection. If you're not comfortable using a multimeter, consult a qualified electrician.

After testing, secure the wires to prevent them from being pulled or damaged. Use cable ties, electrical tape, or wire staples to keep the wires in place. Neat and tidy wiring is not only aesthetically pleasing, but it also reduces the risk of accidental shorts or disconnections. Think of it as organizing your closet—everything is easier to find and less likely to get damaged.

Finally, document your work. Make a note of the connections you made and the type of connectors you used. This will be helpful for future troubleshooting or repairs. You might even want to take a picture of the wiring before you close up the electrical box. It's like creating a treasure map for future you!